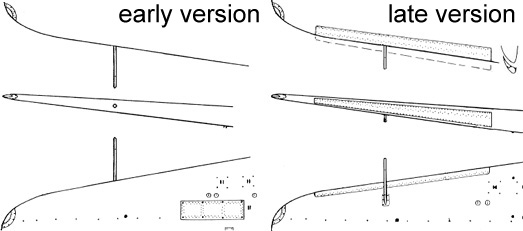

The introduction of slats led to moving the pitot probe from the right wing edge to the lower right wing surface.

|

|

|

|

Modifications to the MiG-3 series

Aircrafts built during the spring were 30 km/h slower than the initial

production aircrafts, this partly due to hurry in production leading to

rough surfaces, partly to the presence of underwing gun pods, introduced

in February.

Many defects were noted during operative use, alongside the already

known weak armament, tendency to spin, longitudinal instability and high

landing speed:

The request for a 1000 km range penalized the MiG-3 and LaGG-3, increasing

their weight; on the contrary, the Yak-1 never satisfied it, so its flight

charachteristics were not impeded by extra weight. In 1941, the only fighter

from the Yakovlev OKB that conformed to it was the I-30, that remained

as only a prototype.

On May 10, 1941, the ventral tank was reduced from 250 l to 140 l to

save weight. Tests on aircraft n. 2859 (with 5 guns) showed that this lightening

improved takeoff, landing, turning and horizontal stability; the time of

turn was reduced by 2-3 s.

| On July 10, 1941, automatic slats were introduced, noticeably improving

the flight characteristics with regards to spinning.

The introduction of slats led to moving the pitot probe from the right wing edge to the lower right wing surface. |

|

|

In the seconf half of 1941 the engine gear reduction ratio changed

from 0.902 to 0.732, and this was associated with a new AV-5L-123 propeller

instead of VISh-22E; the new propeller blades had a pitch angle range of

30° instead of 20°. They are not distinguishable in photos.

Late MiG-3s could have both gear ratios; the installed one was painted on the cowling side to avoid mistakes while mounting the propeller. (left) An armoured glass was installed internally to the windshield.

|

|

|

On some examples, a system to fill tanks with inert gas was installed;

this is recognizable from a small pipe taking exhaust gases from the 2nd

and 3rd left exhaust stacks.

The purpose of this system was to exclude air in the tanks, reducing oxigen on them with obvious safety benefits. This system, although required by early test pilots since 1940, was frequently installed on examples built in summer 1941 and later. |

On April 12, 1941, the order NKAP n.322 ordered to increase the daily

production of MiG-3 to 20 examples, starting from August; this increased

the projected output of MiG-3s during 1941 to 4295 aircrafts.

|

In May 1941, the control surfaces were modified by increasing to 26%

of the aileron compensation, and modifying horizontal tail assembly with

a smaller stabilizer (63% of total area) and enlarged elevator (37% of

total area).

These modifies were tested on 5 examples (nr.3205, 3211, 3214, 3120 and 3169) and approved, but the war prevented their implementation on series aircrafts. |

The late type MiG-3 appears

The engine cowling with dzus locks was considered unsatisfactory and too complex by first line units; according to this, a new cowling inspired to that of Bf-109 was tested at first on the aircraft n.2554, and then introduced into series production from the 16th series (each series was usually composed of 100 aircrafts, so the new cowling should be installed from the aircraft n.3600).

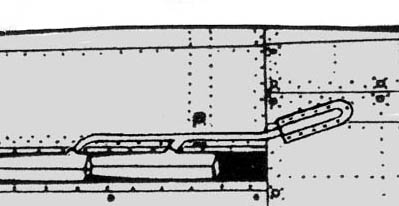

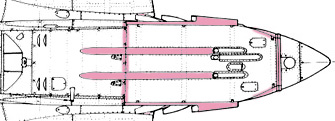

Visible modifications between typical early MiG-3 and typical late MiG-3 were:

|

Left: early type (early characteristics marked with light blue). |

Right, late type (late characteristics marked with pink). |

|

|

|

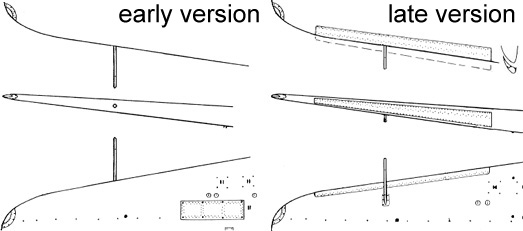

Automatic shutters were introduced in the supercharger intakes on the

wing roots to avoid dust ingestion; they were actioned by the undercarriage

retraction and extraction. (left)

On the earlier aircrafts, only a grille prevents foreign matter ingestion. (right) |

|

On many later examples, forthemost observed during winter 1941/42, the tail wheel was fixed in lower position, while the doors were removed and replaced by a canvas cover; it is not clear if this was made in the factory or on the field.

|

The horizontal stabilizators were modified, apparently enlarging their chord at the tip. |

| On some late examples, a starter tooth was introduced, protruding from the spinner point; differently than on other aircrafts, no any macroscopic step or slot is visible between spinner and tooth. |  |

Modifying the armament

During the summer 1941, tests were made on many armament combinations:

|

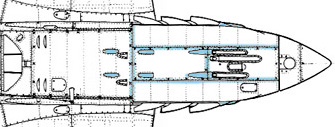

This interesting perspective shows the example n. 5015 produced on late 1941, armed by two machine guns UBS and two built-in batteries of ZROB-82 for the shooting rocket projectiles ROS -82. |